Tegris® Gardner Dart Test

FALLING DART IMPACT TESTING, ALSO CALLED THE GARDNER IMPACT TEST, IS A COMMON, ESTABLISHED TECHNIQUE USED TO MEASURE THE TOUGHNESS OR IMPACT RESISTANCE OF PLASTIC MATERIALS

GARDNER DART TEST | TEGRIS® THERMOPLASTIC COMPOSITE SHEET L8 | LABORATORY VERIFICATION ANALYSIS | APRIL 2025

The test is widely employed for several key purposes—

To determine if a plastic is suitable for applications where it might be subjected to sudden impacts.

To set quality specifications for materials.

To assess how finishing processes (like painting or welding) or environmental conditions affect the plastic's ability to withstand impact.

Some applications require that plastics have specific properties to withstand the environmental factors and forces expected for their intended application. Gardner Dart Tests yield insightful results that aid in the product design and material selection processes.

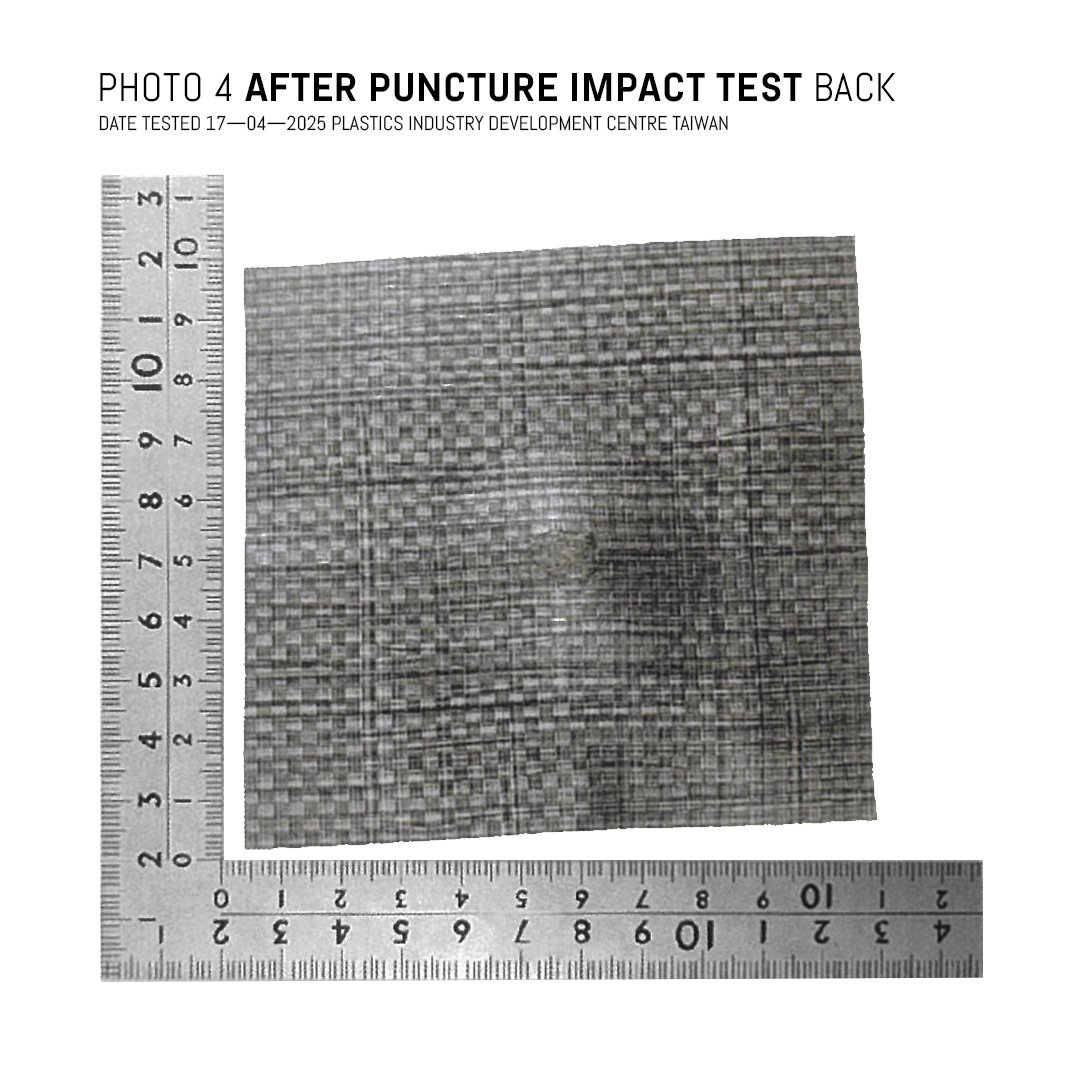

The test procedure involves placing a sample on a base plate with a specified diameter opening. An impactor, featuring a nose of a specific radius, is then centered on top of the sample. A predetermined weight is raised to a specific height within a guide tube and subsequently released, allowing it to free—fall onto the impactor and force its nose through the test sample. The recorded data includes the drop height, the weight used, and the final pass/fail result of the test.

The data from falling dart impact tests is typically analyzed using the Bruceton Staircase method. This technique utilises a series of samples to approximate the energy level at which the material will transition from passing to failing the impact test. After this initial bracketing, 20 consecutive impacts are conducted. If a test sample passes the impact, the drop height for the next test is increased by one unit; if it fails, the height is decreased by one unit. The results from these 20 impacts are then used to calculate the Mean Failure Height—the specific point where, statistically, 50% of the test samples can be expected to fail upon impact.

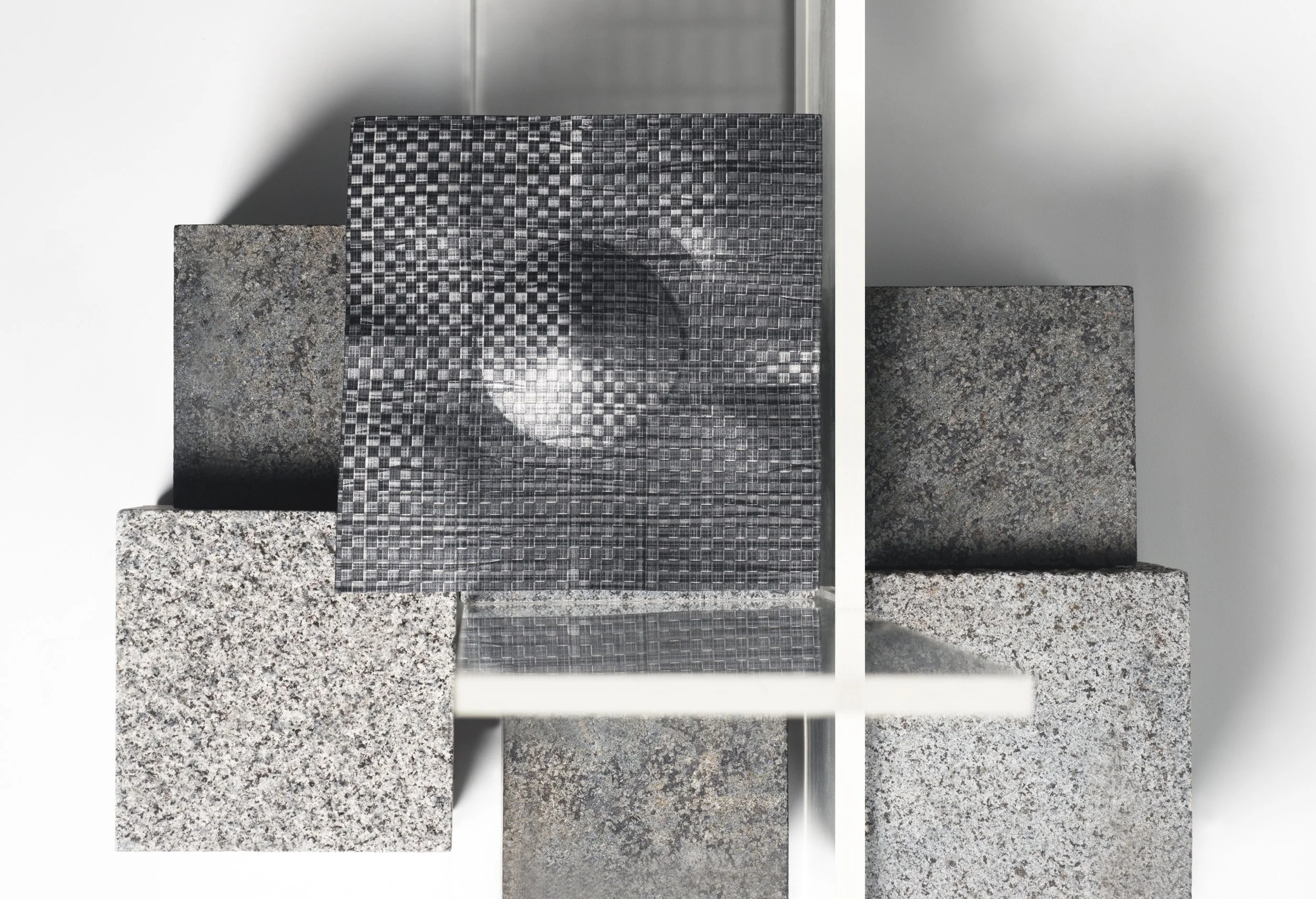

Tegris®, a polypropylene (PP) based thermoplastic composite material, is specifically engineered for lightweight strength and superior impact performance and is often used in military, automotive, aerospace and high—durability consumer goods. Additionally, it allows for the creation of a wide variety of internal structures. A single layer of Tegris® is 0.005" (0.132MM) thick and weighs 0.02 lbs/ft² (0.11 Kg/m²) allowing it to be tuned to a high degree of precision based on impact or rigidity needs. This attribute also makes it an excellent, ultra light but strong, stiffener in the form of inner liners or inserts for products in diverse areas such as military tactical gear, sports equipment or aerospace.

By leveraging the inherent properties of Tegris® and conducting rigorous testing, such as the Gardner Dart Test, Moora ensures the material meets specific performance and safety standards. This validation allows Tegris® to effectively replace heavier, traditional alternatives like carbon fibre or glass—filled composites, providing equal or superior performance with a significant reduction in overall weight.